The term hybrid has gained in popularity in recent years, largely thanks to the development of petrol/electric hybrid vehicles. But the idea isn’t just confined to cars. In fact, a hybrid can be any fusion of technology or techniques that’s used to create a more efficient or improved product.

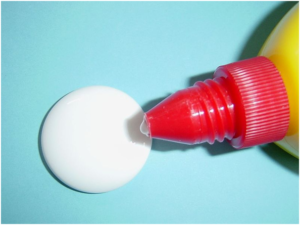

In the building sector it can be used to refer to materials that combine different qualities – for example, a roof sealant that combines the best qualities of silicone and polyurethane compounds. These innovative sealants and adhesives allow materials that might not normally work well together – such as glass and concrete – to be joined successfully.

Creating Hybrids

For manufacturers of adhesives and sealants, hybrid techniques allow them to create specific material characteristics that might not otherwise have been possible. Of course, this is not really new. For many years people have been experimenting with combining materials, and there are even many examples of hybrids in the natural world – things like teeth, which are made from a combination of materials, for example.

When creating a hybrid roof sealant, the makers can aim to introduce specific characteristics. These might be, for example, to make the sealant harder-wearing or to reduce odour, improve UV resistance or to remove hazardous substances from the composition.

Advantages of Hybrids

In the construction industry the use of hybrid sealants and adhesives can deliver many different advantages. They can be made to resist high temperatures, for example, or to adhere without the need to apply a primer first. They can also be formulated to make life easier for the user by having a fast drying time or ensuring that they have a long shelf life before deteriorating.

There are advantages for the end user too. Hybrid sealants are greener because they can be made free from solvents, silicones and other hazardous chemicals. But they can also be made to combine characteristics such as the ease of application typically associated with silicones and the strong mechanical qualities of polyurethane. This means that there is strong demand for hybrid materials across the industry, and new ones are continually being developed and refined in order to meet the demand from the building industry for high-quality sealants and adhesives that offer top performance and optimum ease of use at an affordable price.